Chiller and Redundant Plant Removal

Chiller and Redundant Plant Removal

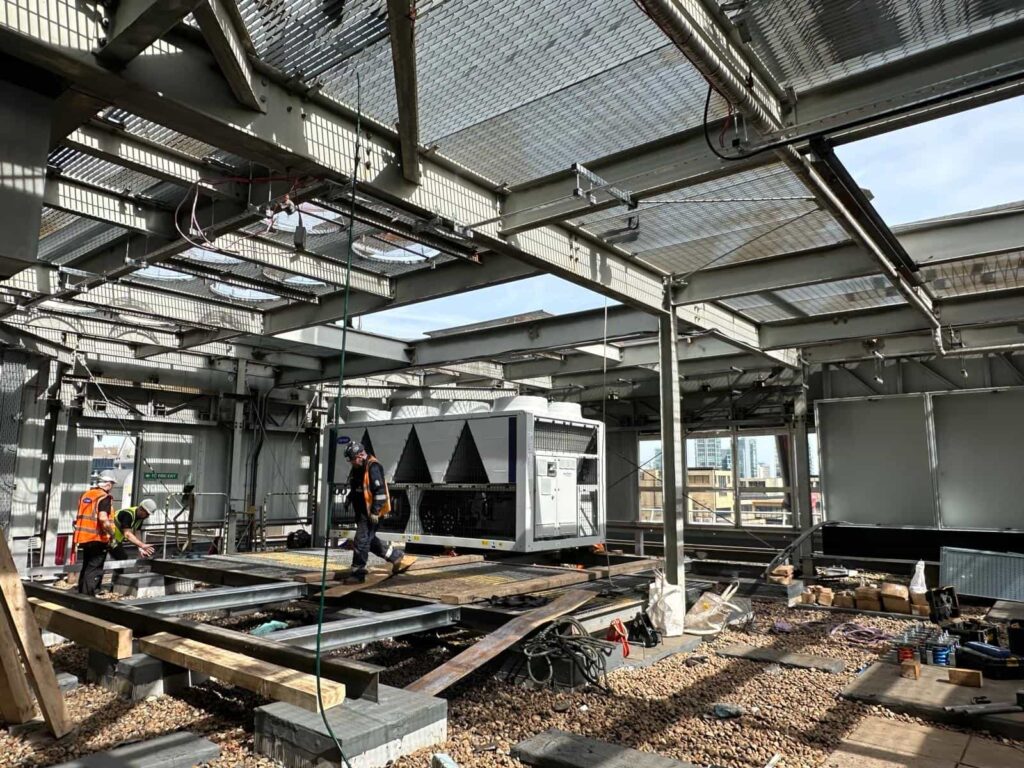

Finch of Bookham recently undertook a detailed project to remove redundant items from the roof and install new chillers. This project involved careful planning, precise execution, and strict adherence to safety guidelines to ensure the successful completion of the lifting and positioning tasks.

Delivery and Setup

W Finch & Co Ltd team underwent a toolbox talk with the site supervisor to discuss the scope of work. The crane and transport were then positioned by the Lift Supervisor in conjunction with the lift plan and council recommendations, ensuring the crane was set up according to the manufacturer’s guidelines and the specifications.

Lifting and Transporting Redundant Items

Two two-leg chains were attached to the crane hook and slings. The crane hook was positioned above the centre of the load, and the chains were attached. The redundant items were lifted from the roof, hoisted to clear the roof, and slewed onto the awaiting transport. In conjunction with the slinging arrangements of the chillers, spreaders were attached to the chains, and rollers, wire ropes, and nylon slings were attached to the underside of the spreaders.

Chiller Installation

The crane hook was positioned above the center of the first chiller, which was then slung according to the manufacturer’s lifting points. Under the direction of the W Finch & Co Ltd designated banksman, the crane hook was raised until the slinging arrangement was secure.

The lifting equipment was checked by the slinger, and a hand line was attached to the chiller to assist in its control during the lifting process. The chiller was lifted from the transport onto the roof and guided through the aperture, landed on the steelwork with 12,000 kg machine skates, and positioned. Once the base was in position, the chiller was lowered onto AVMs at the confirmed location, a process repeated for the second chiller.

Upon completion, we skated the complete containerized generator back onto the plinth. Once all works were finished, all lifting and moving equipment was removed from the building in the reverse procedure.